HYOSUNG Pok flame retardant V0 model m33af2y chemical resistant

Model No.︰M33AF2Y

Brand Name︰HYOSUNG

Country of Origin︰Korea

Unit Price︰CNY ¥ 50 / KG

Minimum Order︰25 KG

Product Description

POKETONE Polymer M33AF2Y

POKETONE Thermoplastic Polymers arealiphatic polyketones, a revolutionary new classof semi-crystalline thermoplastics. Hyosung developed new catalyst to produce this uniquepolymer at in 2013 and constructed commercialplant in 2015, in Ulsan, Korea.

POKETONE Polymer M33AF2Y is a flameretarded high-flow injection moulding gradewith mechanical properties which classify it as an engineerring thermoplastic. This grade offersUL94 V-0 rating, high comparative tracking andglow-wire indices, all without the use of halogenated or red phosphorus flame retardants.

The benign flame-retardant system used for POKETONE Polymer M33AF2Y ensures thatthe smoke density and toxicity are both low. Yet this grade retains the exceptional blend ofproperties of the base polymer, such as lowmoisture absorption, good toughness and high resistance to a wide range of chemicals.

POKETONE Polymer M33AF2Y is anadvanced high-flow, low-viscosity polymer that should be considered for mouldings with long flow paths or thin walls. This grade is very easy to process on standrad injection moulding equipment. Cycle times are generally short.

Parts show good mould definition with glossy mar-resistant surfaces. POKETONE Polymer’s low moisuture sensitivity means that no conditioning of parts before assembly or use is necessary.

Applications of POKETONE Polymer M33AF2Y may be found in the automotive, electrical, electronics, industrial and consumer applicance markets.

Overview

- Unique engineering plastic, the polymer of which backbone consists of only Carbons.

- Highly crystalline with compact crystal structure

- Excellent impact resistance, abrasion resistance,chemical resistance,fuel resistance,gas barrier properties

After developing proprietary technologies, Hyosung Corporation is producing POKETONE in the 50,000 tons per annum commercial plant located in Yongyeon, Ulsan, Korea.

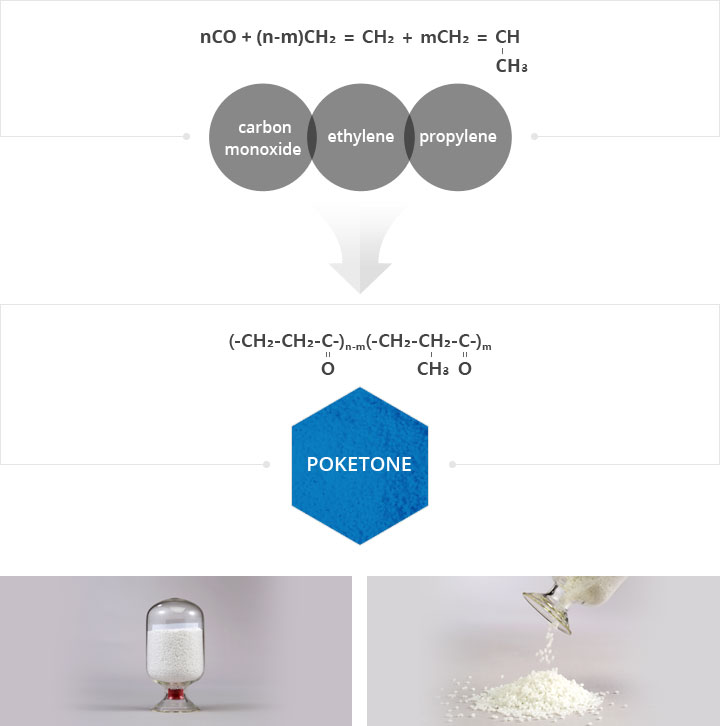

Definition

POKETONE is a tough semi-crystalline thermoplastic which has perfectly alternating structure of Carbon monoxide and Olefin.

Structure

POKETONE is the unique engineering plastics, the backbone of which is composed of only Carbons. Its flexible chains together with the molecular symmetry enhances crystallization which results in many differentiated properties such as excellent chemical and impact resistance, exceptional wear resistance and barrier properties.

Properties

High impact strength

POKETONE has high impact strength taking advantages of relatively flexible CO/Olefin polymer backbone.

Excellent chemical resistance

POKETONE is highly resistant to automotive fluids, hydrocarbon solvents, salts, and weak acids and bases.

Excellent wear resistance

POKETONE has excellent wear resistance even better than POM and reduces various noise issues.

Exceptional barrier properties

The gas and hydrocarbon barrier properties of POKETONE is exceptional as similar to EVOH that is at the highest level of all existing polymers.

Portfolio

We supply several injection molding and extrusion grades with the range of Melt Flow Index(g/10 min) from 3 to 250, and Melting Temperature(℃) from 195 to 235.

Please contact us for more details.

Product Image